Brief Introduction of the Machine

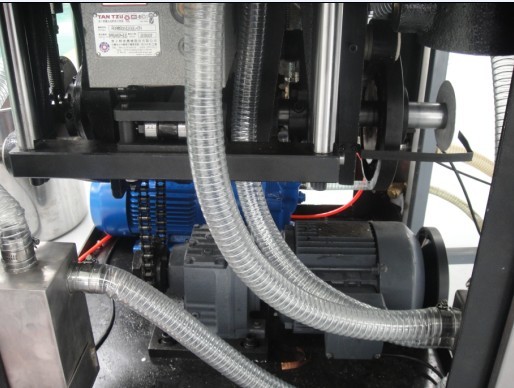

PLC control and electrical components choose the international famous brand, such as MITSUBISHI, SIEMENS, SCHNEIDER, OMRON and so on, nicely, safely, reliably. Screen control with computer windows scenically, advanced efficient. Advanced SEW motor and SIEMENS vacuum pump guarantee the stability of the machine.

The machineadopt the High-teach imported cam graduation system, which graduation precision, compact structure, low noise.

01. Stainless steel main machine housing.

02. Filling rate up to 99% suitable for capsule size “00”” to Size “5”

03. Multi-vent plugging filling, intermittent motion and frequency control

04. PLC touch screen controller

05. Dust collector and water circulating vacuum pump included

06. Sensor system – alarming first and then stopping machine when any one is happened as following situation.

A. without powder or pellet

B. without capsules

C. open the plastic door

D. Dust collector, vacuum pump and feeder motor are overload

E. Inverter is in trouble

07. Electrical control system.

A. Rapidity display.

B. Abnormal station display.

C. Frequency of Inverter display

D. Main motor state

08. 1 set size change parts for main machine.

09. Spare parts for one year, tool kit & operation manual.

10. Export Standard package.

11. IQ/OQ with the machine.

Main configuration table

PLC | OMROM |

Vacuum Pump | SENEX |

Touching Screen | EVIEW |

Dividing Box | TANTZU |

Sensor | OMROM |

Main motor | Germany SEW |

Linear Bearings | Japan HIT |

proximity switch | OMROM |

transducer | Delta |

contactor | France Schneider |

protector | France Schneider |

print

print close

close